-

×

Ambersil Cold Galvanise 400ml

1 × £12.90

Ambersil Cold Galvanise 400ml

1 × £12.90 -

×

Tyrolit Cutting Disc 350mm x 25.4mm x 2.8mm (14”). Box of 10

1 × £53.70

Tyrolit Cutting Disc 350mm x 25.4mm x 2.8mm (14”). Box of 10

1 × £53.70 -

×

Jasic EVO 2.0 TIG200P AC/DC PFC

1 × £1,258.60

Jasic EVO 2.0 TIG200P AC/DC PFC

1 × £1,258.60 -

×

Parweld XTE181C Compact Automotive MIG Machine 230V

1 × £514.30

Parweld XTE181C Compact Automotive MIG Machine 230V

1 × £514.30 -

×

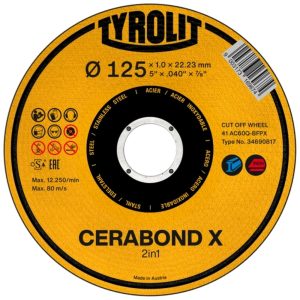

Tyrolit Cerabond X Cut-off Wheels 115mm. Box of 25

1 × £65.00

Tyrolit Cerabond X Cut-off Wheels 115mm. Box of 25

1 × £65.00 -

×

Parweld XR943A Air-Fed Welding and Grinding Helmet

1 × £459.99

Parweld XR943A Air-Fed Welding and Grinding Helmet

1 × £459.99 -

×

CROS-ARC 423C MIG 415V

1 × £1,592.00

CROS-ARC 423C MIG 415V

1 × £1,592.00 -

×

EWM Picomig 225 Puls TGK MIG Welder 240v

1 × £2,690.00

EWM Picomig 225 Puls TGK MIG Welder 240v

1 × £2,690.00 -

×

Optrel Weldcap

1 × £159.50

Optrel Weldcap

1 × £159.50 -

×

Weldgas Gas Pre-Heater

1 × £699.43

Weldgas Gas Pre-Heater

1 × £699.43 -

×

Optrel Helix Quattro Welding Helmet

1 × £518.00

Optrel Helix Quattro Welding Helmet

1 × £518.00 -

×

Weldgas Single Stage Economy 2-Gauge Acetylene Regulator (Base Entry)

1 × £34.95

Weldgas Single Stage Economy 2-Gauge Acetylene Regulator (Base Entry)

1 × £34.95 -

×

Jasic MIG 450S Inverter Welder 415V

1 × £2,852.50

Jasic MIG 450S Inverter Welder 415V

1 × £2,852.50 -

×

Jasic Cut 160 Plasma Cutter 415V

1 × £3,498.60

Jasic Cut 160 Plasma Cutter 415V

1 × £3,498.60 -

×

HMT VersaDrive Extra Long Holesaw Guide Pin

1 × £36.26

HMT VersaDrive Extra Long Holesaw Guide Pin

1 × £36.26 -

×

Miller Wired Foot Control Pedal

1 × £322.98

Miller Wired Foot Control Pedal

1 × £322.98 -

×

HMT VersaDrive Extra Long Holesaw Pilot Pin

1 × £20.65

HMT VersaDrive Extra Long Holesaw Pilot Pin

1 × £20.65 -

×

Optrel Helix Quattro Air Fed Welding Helmet System

1 × £1,169.00

Optrel Helix Quattro Air Fed Welding Helmet System

1 × £1,169.00 -

×

Arc Torchology M5 Tip Adaptors – Pack of 5

1 × £21.30

Arc Torchology M5 Tip Adaptors – Pack of 5

1 × £21.30 -

×

JEI 19mm shank Adaptor

1 × £8.30

JEI 19mm shank Adaptor

1 × £8.30

Subtotal: £15,987.96